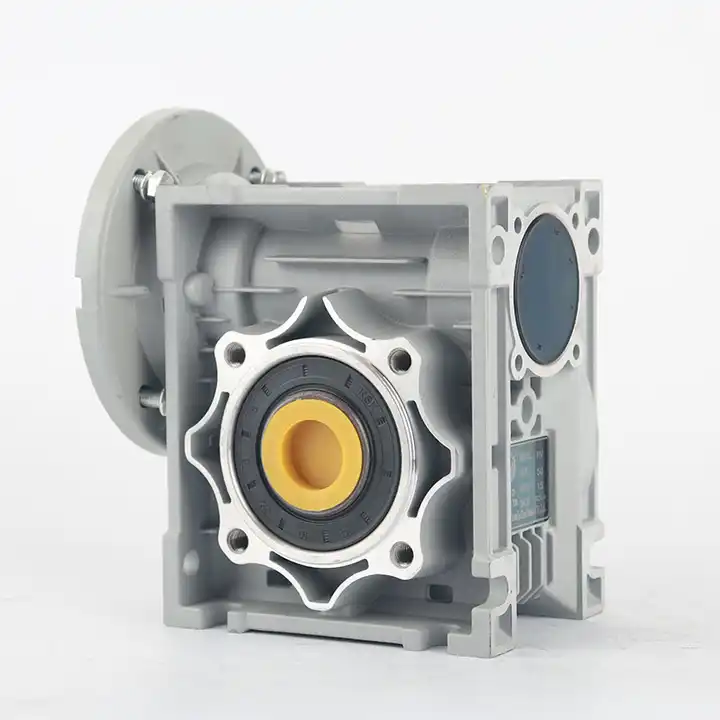

worm gearbox

HIGH QUALITY HIGH PRECISE MANUFACTURER & SUPPLIER

What Is A Worm Gearbox?

A worm gearbox, also known as a worm gear reducer or worm drive, is a type of gearbox that is designed to transmit power at a right angle. It consists of two main components: a worm gear and a worm wheel. The worm gear is a threaded rod that is driven by a motor, while the worm wheel is a gear that is shaped like a screw and meshes with the worm gear.

The design of the worm gearbox is such that the worm gear and worm wheel have a large contact ratio, meaning that they have a large number of teeth in contact at any given time. This results in a very strong and stable gear system that is able to handle high loads with ease. The worm gear and worm wheel are usually made of high-strength materials such as bronze, steel, or cast iron.

Worm Gearbox For Sale

Worm Gearbox manufacturers, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don’t worry; uploaded. You can email us directly, and we will reply within 24 hours!

-

24v dc worm gear linear servo gear motor gearbox worm drive gearbox worm gear motor

-

Aluminum gear reducer worm gearbox

-

DC Motor Small Self-locking Worm Gearbox

-

High quality gear type worm reducer

-

High Quality Involute Spur Gear Customized Gear Worm Reduction Gearbox

-

Motor Worm Gearbox with Input Shaft Spur Gear

Application of Worm Gearbox

Lifts and elevators

Worm gears are used in lifts and elevators because they can provide high gear ratios and self-locking properties. This means that the elevator will not be able to move unless the worm gear is turning, which helps to prevent accidents.

Conveyor belts

Worm gears are also used in conveyor belts because they can provide high torque and low speeds. This is ideal for conveyor belts that need to move heavy loads over long distances.

Machine tools

Worm gears are used in machine tools such as lathes and milling machines because they can provide high torque and precise control. This is important for machine tools that need to be able to make accurate cuts.

Winch and hoists

Worm gears are used in winches and hoists because they can provide high torque and slow speeds. This is ideal for winches and hoists that need to be able to lift heavy loads slowly and carefully.

Rudders

Worm gears are used in rudders because they can provide high torque and precise control. This is important for rudders that need to be able to change the direction of a ship or boat quickly and accurately.

Worm drive saws

Worm drive saws use worm gears to provide high torque and low speeds. This is ideal for saws that need to be able to cut through thick materials with ease.

How an Worm Gearbox works?

A worm gearbox is a gear arrangement in which a worm (which is a gear in the form of a screw) meshes with a worm wheel (which is similar in appearance to a spur gear). The worm gear is typically made of steel, while the worm wheel is typically made of bronze.

The worm gear rotates on a shaft, and the worm wheel is attached to another shaft. When the worm gear rotates, it engages with the teeth of the worm wheel. This causes the worm wheel to rotate, and the output shaft to turn as well.

The worm gear and worm wheel have a very high gear ratio, which means that the output shaft will rotate much slower than the input shaft. This is because the worm gear has a much smaller number of teeth than the worm wheel.

The worm gear also has a self-locking feature, which means that it will not rotate unless the input shaft is turning. This is a safety feature that can help to prevent accidents.

Worm Gearbox Advantage

High torque output

Worm gearboxes are designed to provide high torque output with low-speed operation.

Precision positioning

Worm gearboxes have low back-driving characteristics, which means that they maintain their position even when the motor is not actively driving them.

Efficiency

Worm gearboxes have a high level of efficiency due to the minimal number of moving parts and the low amount of back-driving.

Compact size

Worm gearboxes are relatively compact in size, which makes them ideal for applications where space is limited.

Quiet operation

Worm gearboxes operate with minimal noise, which makes them ideal for applications where noise levels need to be kept to a minimum.

High reduction ratio

Worm gearboxes can achieve high reduction ratios, which means that they can produce high torque output at low speeds.

How To Maintain The Worm Gearbox?

Here are some tips on how to maintain a worm gearbox:

Lubrication: Proper lubrication is essential for the long-term health of a worm gearbox. The type of lubricant used should be appropriate for the operating conditions and the gearbox design. In general, a high-quality, anti-wear lubricant is recommended. The oil level in the gearbox should be checked regularly and topped up if necessary.

Inspection: The gearbox should be inspected regularly for signs of wear, damage, or leaks. If any problems are found, they should be corrected as soon as possible to prevent further damage.

Cleaning: The gearbox should be cleaned regularly to remove dirt, debris, and other contaminants. This will help to prolong the life of the gearbox and prevent premature wear.

Storage: When the gearbox is not in use, it should be stored in a dry, clean, and cool environment. This will help to prevent corrosion and other forms of damage.

WHY CHOOSE US?

We are one of the best worm gearbox manufacturers. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!